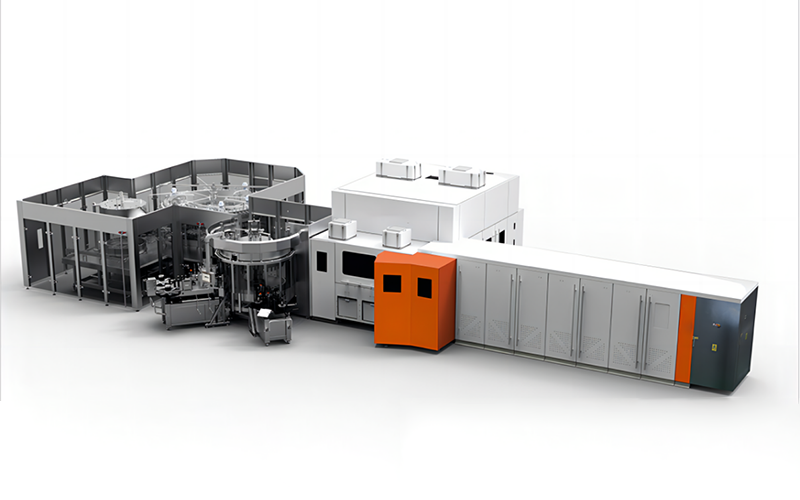

ZPACK desea informarle que contamos con una nueva máquina de soplado. Además, seguimos avanzando con una máquina única que nos permite automatizar el proceso de producción de plástico para hacerlo mejor, más rápido y más preciso. Utilizamos un proceso conocido como soplado, que nos permite producir una variedad de productos plásticos, como botellas y recipientes. Esta tecnología es muy importante porque también permite la producción de piezas plásticas con alta precisión en pequeños lotes. También asegura que cada producto que producimos cumple con nuestros extremadamente altos estándares de calidad. Nuestra máquina de soplado nos permite fabricar una amplia gama de productos plásticos soplados en una igualmente gran variedad de formas y tamaños. Por lo tanto, la máquina de envasado de jugos automática máquina de soplado es una de las herramientas más importantes en nuestro proceso de producción.

La tecnología de soplado está revolucionando la forma en que se fabrican los productos plásticos hoy en día. Nuestra nueva máquina de soplado nos permite producir productos plásticos más rápido y fácil que nunca. Que precio de la máquina de llenado automático significa que invertimos menos tiempo y menos recursos en crear los productos que nuestros clientes desean. No solo nos permite construir cosas más rápidamente, sino que también mejora la sostenibilidad de nuestro proceso de fabricación. Nuestra tecnología de moldeo por soplado también puede producir productos plásticos de alta resistencia, sin costuras y con superficie lisa, capaces de satisfacer diversas necesidades del consumidor. Por tanto, esto representa una situación ventajosa para todas las partes involucradas.

Todas nuestras máquinas de soplado producen productos plásticos fuertes y suaves. Entrenadas hasta octubre de 2023[50–53] Esta máquina increíble nos permite personalizar piezas plásticas adaptadas a máquina de procesamiento de agua carbonatada automática ¡El detalle más extremo! Como tal, cada producto que diseñamos está libre de defectos y cumple con nuestros estrictos estándares de calidad. Nuestra máquina de soplado ofrece un acabado superficial suave y uniformidad dimensional. Esto los hace ideales para todo tipo de aplicaciones. Como innovadores fabricantes de soplado, ofrecemos soluciones importantes para las botellas que buscas — desde botellas, hasta contenedores y mucho más. Todo lo que producimos gira en torno a la calidad y la eficiencia.

Podemos fabricar más rápido y generar menos residuos gracias a nuestra tecnología de soplado. La máquina de soplado que tenemos puede producir productos plásticos a una mayor velocidad y con mayor precisión. Este sitio nos ayuda a responder mejor a las necesidades de los clientes. Además, esto máquina de llenado automática para jugo, miel y líquidos la tecnología minimiza los desechos a través de varios métodos para optimizar el uso de materiales, como limitar la posibilidad de rehacer o cometer errores. Nuestro preform se produce utilizando una máquina de soplado, lo que hace que los productos fabricados con él no solo sean de alta calidad sino también sostenibles y amigables con el medio ambiente. Esto alinea nuestros esfuerzos con prácticas de fabricación responsables y esfuerzos por la sostenibilidad, haciendo nuestra parte para preservar la salud de nuestro planeta.

Acerca de ZPACK: En ZPACK, creemos en llevar ideas inteligentes e innovadoras a la vida al proporcionar lo mejor en embalaje plástico a través de nuestras máquinas de soplado. Fabricamos máquinas que producen una variedad de contenedores y botellas plásticas fuertes, herméticas y estéticamente agradables. Usando nuestra tecnología propia de soplado, fabricamos soluciones de embalaje personalizadas que se adaptan a las necesidades específicas de nuestros clientes. Esto podría incluir, por ejemplo, artículos que necesite para alimentos, bebidas, productos de cuidado personal u otros bienes. No solo entregamos embalajes plásticos funcionales y útiles, sino también aquellos con un aspecto impresionante y perfecto para hacer que nuestros clientes sean más atractivos y notorios en el mercado, atrayendo así a más clientes. Con las máquinas de soplado de ZPACK, puede confiar en un embalaje plástico de alta calidad que línea Automática de Envasado de Bebidas Carbonatadas cumple perfectamente con sus especificaciones y supera sus expectativas. ¿Cómo podemos ayudarle a tener éxito?

Ofrecemos productos de bajo costo así como productos personalizados y diseñados a medida. Ponemos mucho énfasis en la calidad de nuestros productos en las máquinas de soplado. Nuestro equipo se somete a pruebas extensas para asegurar que funcione sin problemas. Nos adherimos a estrictos estándares de control de calidad y empleamos métodos modernos de prueba para asegurarnos de que cada equipo esté en línea con nuestros estándares antes de ser enviado a nuestros clientes.

Estamos muy orgullosos de nuestra capacidad para ofrecer precios bajos sin sacrificar la calidad. Al confiar en nuestra propia fábrica, podemos eliminar la necesidad de intermediarios y así evitar aumentos costosos de precios. Esto nos permite trasladar los ahorros a nuestros clientes y asegurarnos de que obtengan la mejor relación calidad-precio.

Servicio posventa de por vida y un compromiso inquebrantable con la calidad que protege su equipo en cada etapa del proceso. Sabemos que las capacidades de un producto no terminan con su compra. Ofrecemos una gama completa de soporte tras la venta para garantizar la satisfacción de nuestros clientes. Creamos un grupo exclusivo de soporte posventa para cada cliente, asegurando un servicio rápido y eficiente. Si surge algún problema, responderemos dentro de la máquina de moldeo por soplado y proporcionaremos soluciones en un plazo de 8 horas. Asimismo, ofrecemos un período de garantía ampliado, y nuestro personal de soporte siempre está disponible para ayudarle con cuestiones técnicas.

Nos especializamos en la producción de equipos de alta tecnología y soluciones de máquinas de moldeo por soplado para clientes globales. Como una empresa nacional de alta tecnología altamente reconocida, contamos con un formidable poder tecnológico y científico en investigación y desarrollo. Nuestro equipo está compuesto por expertos e innovadores del sector que impulsan los límites de la tecnología para desarrollar soluciones innovadoras. Garantizamos que nuestros productos y servicios se mantengan a la vanguardia de los avances tecnológicos, proporcionando a nuestros clientes una ventaja en el mercado