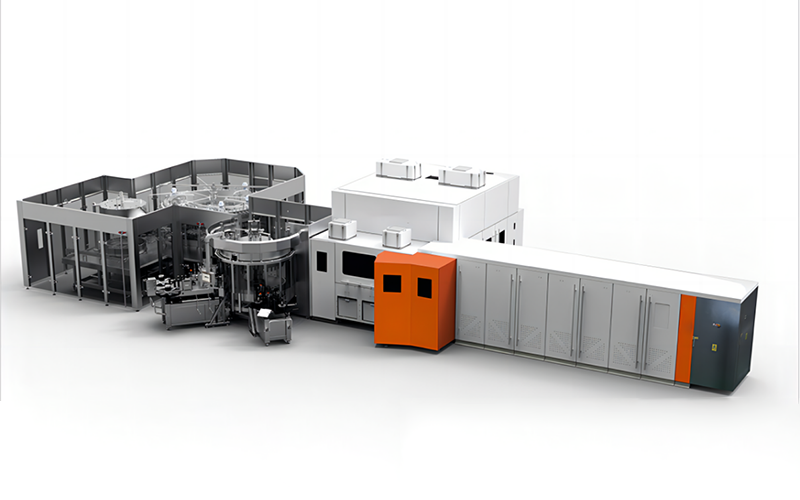

ZPACK wishes to inform you that we have a new blow moulding machine. And we follow up with a unique machine that allows us to automate the process of plastic production to make it better, faster and more precise. We use a process known as blow moulding which enables us to produce a variety of plastic products such as bottles and containers. This technology is very important because it also enables high-accuracy production of plastic parts in small batches. It also ensures that every product we produce meets our extremely high standards for quality.” Our blow moulding machine allows us to manufacture a very extensive array of blow-moulded plastic products in an equally large variety of shapes and sizes. Therefore, the automatic juice filling machine blow moulding machine is one of the most important tools in our production process.

Blow moulding technology is revolutionising how plastic products are manufactured today. Our new blow moulding machine allows us to produce plastic products faster and easier than ever. That automatic filling machine price means we expend less time and fewer resources at creating the stuff our customers want. Not only does that technology help us build things faster, but it also helps us improve the sustainability of our manufacturing process. Our blow moulding technology can also produce high-strength, seamless and smooth plastic products that can meet different consumer needs. So this is a more win-win for all involved.

All our blow moulding machine makes strong and smooth plastic products. Trained until October 2023[50–53]This awesome machine lets us customize plastic pieces tailored to automatic carbonated water processing machine the uttermost detail! As such, every product we deSIGN is free of defects and meets our stringent quADITY standards. Our blow moulding machine offers smooth surface finish and dimensional uniformity. This makes them ideal for all kinds of applications. As innovative blow moulders, we provide major solutions to the bottles you seek — from bottles, to containers and much more. Everything we produce is centered around quality and efficiency.

We can manufacture faster and cause less waste through our production thanks to blow moulding technology. The blow moulding machine we have can produce plastic products at a much greater speed and with higher accuracy. This site helps us to better respond to customer needs. Moreover, this automatic juice honey liquid filling machine technology minimizes waste through various ways to optimize material utilization, such as limiting the chance for rework or mistakes. Our preform is produced using a blow moulding machine, which makes the products made from it not only high-quality but also sustainable and eco-friendly. It aligns our efforts with responsible manufacturing practices as well as sustainability efforts—doing our part to preserve the health of our planet.

About ZPACK: At ZPACK, we believe in bringing smart, innovative ideas to life by providing the best in plastic packaging through our blow moulding machines. We manufacture the machines that produces a variety of strong, leak-proof, and aesthetically pleasing plastic containers and bottles. Using our proprietary blow moulding technology, we manufacture custom packaging solutions that are tailored to the specific needs of our customers. This could include, for example, items you need for food, drinks, personal care products, or items of other goods. We deliver not only functional and useful plastic packaging but also the one with an impressive and perfect look so as to make our customers more attractive and noticeable in the market thereby grabbing more customers. With ZPACK's blow moulding machines you can rely on high-quality plastic packaging that automatic carbonated drinks filling line perfectly meets your specifications and exceeds your expectations. How can we help you succeed!

We provide low-cost products as well as custom-designed, customized products. We place a lot of Blow moulding machine on the quality of our products. Our equipment is subjected to extensive testing to ensure that it operates flawlessly. We adhere to strict quality control standards and employ modern methods of testing to ensure that each piece of equipment is in line with our standards prior to when it is shipped to our customers.

Blow moulding machine are very proud of our ability to offer low prices without sacrificing quality By relying on our own factory we can eliminate the need for middlemen so we can avoid costly cost increases We are able to pass savings to our clients and make sure they receive the most value for money

Lifetime after-sales service and unwavering commitment to quality that protects your equipment at each step of the way. We know that a product's capabilities don't end with its purchase. We offer a full range of support following sales to ensure our customers satisfaction. We create an exclusive after-sales support group to each customer, guaranteeing prompt and efficient service. If any issues arise we will reply within Blow moulding machine and provide solutions within 8 hours. We also provide a longer warranty period, and our support staff is always available to assist with technical issues.

We specialize in the production of high-tech equipment and Blow moulding machine solutions for global customers As a highly-regarded national high-tech enterprise we possess a formidable technological and scientific research and development power Our team is made up of industry experts and innovators who push the boundaries of technology in order to develop innovative solutions We ensure that our products and services remain in the forefront of technology advancements supplying our customers with an edge in the market