Are you tired of filling those slow wet containers? I want to be clear here and now, this is all a bit of teeth pulling. Faster + Better Bottle Filling? If that is the case, then perhaps you are in need of a weighing liquid filling machine?

Liquid filling device is once such machine that makes the task all easy with just fill necessary amount only, irrespective of how much order come. It is a wonder tool for the companies that are manufacturing their products at high-speed volume. It is used for packing all types & / of liquids it depending upon product and pack volume cfgf machine works with any type bottle or jar. These stickers or magnets have been coated with a few of these everyday household liquids - had liquid hand soap, water + oil. You can to do more operations only in one machine!

Filling fillerA weighing fillera weighing type of filling machine that does the most accurate true weight for each individual container. This machine fills container with liquid say glass of standard quantity weight because in mean time it just measure the capacity of type kind and sec empty ccondition. The machine will pivot back and forth until its target weight is reached, to hundredths or tenths of an ounce, more juice in and others adjust out. You always receive the right amount, no more guessing!

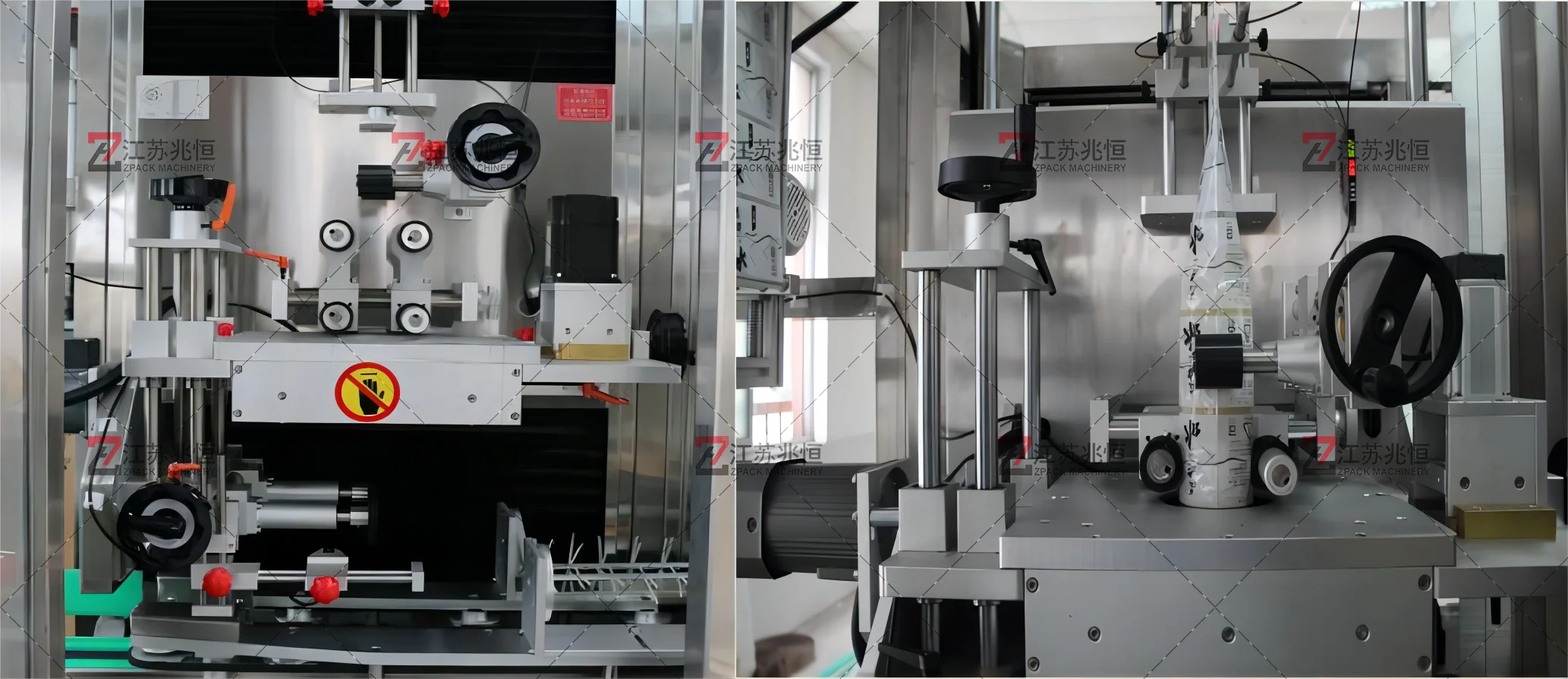

Those latest weighing liquid filling machines are what we call the ones working at light speed. New technologyThey load containers much faster than the outdated models and are great for high throughput production lines where speed is everything. A special sensor and intelligent computer software are used in these advanced machines, so as to accurately pour a particular volume of liquid into every single bottle the machine processes. Which means fewer errors and an easier workflow.

The Corners That Exist This is so because only when using a weighing liquid filling machine we can save water and also make less error during juice bottling process(Juice Bottling Plant). This machine is designed to measure the precise amount of slurry in all containers. This way you do not have to worry about having to pour them, very often we end up spilling it and that is another loss. Letting go of the guessing manually saves you time and guarantees that every basket is perfectly stacked.

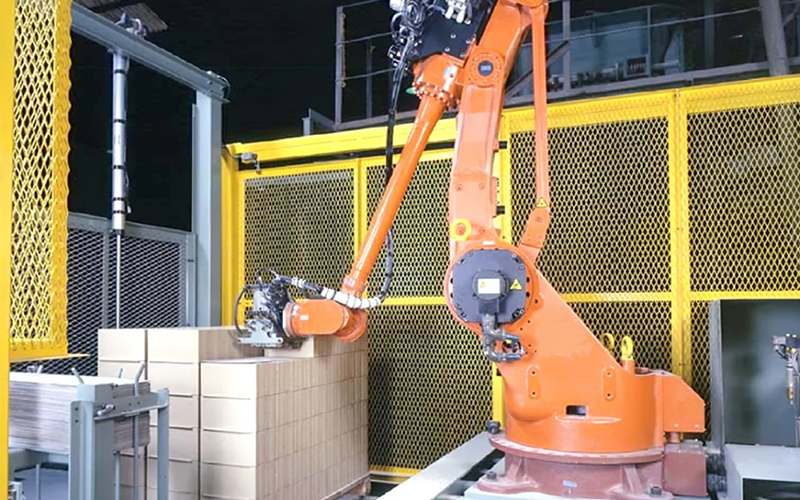

This is the fastest and most precise way of putting liquid into packages with it comes to automated Liquid Weigh Fillers. Once empty, the tanks are collected and delivered to a refilling station by robotic arms. A set amount of liquid is added as soon as the container has been installed, and it precisely measures this from what exactly was relocated to guarantee everything went. This all process is very quick and accurate that makes it a fit for high-speed production lines where the speed needs to work with precision.

weighing liquid filling machine in the development of cutting-edge equipment and offering solutions to clients across the world We are a high-tech firm that is nationally recognized Our capabilities in research and development are unbeatable Our team of experts are comprised of leaders in the industry and innovators who are constantly challenging the limits of technology to create innovative solutions Our products and services stay ahead of technological advances thereby providing our customers with an competitive edge

We offer competitive products as well as custom-designed products. Our weighing liquid filling machine is quality. Our equipment is subjected to extensive testing to ensure that it operates flawlessly. We adhere to the strictest quality control guidelines and use state-of-the-art testing methodologies to ensure that each piece of equipment is in line with our strict standards before it is handed over to our clients.

We offer a lifetime support after sales service and a pledge to quality. This will ensure the safety of your equipment at every step. We offer a full range of support following sales to ensure our customers satisfaction. Every customer has a dedicated weighing liquid filling machine of after-sales guarantee to ensure prompt and efficient service. If there are any issues our team will address the issue within two hours and offer an answer within 8 hours. We also provide a longer warranty period, and our maintenance staff is always available to assist with technical problems.

We are extremely proud of our ability to offer low prices without sacrificing quality Through our own physical factory we are able to eliminate the need for middlemen thus avoiding any weighing liquid filling machine price increases We can pass these savings to our clients and ensure they receive the most value for money