If you have ever noticed those bubbles in your favorite soda or sparkling water then you know what i am talking about. The bubbles are what makes the drink a carbonated beverage! Soda is popular almost everywhere, because it's bubbly, festive and fun to drink. These effervescent beverages are available in a variety of flavors including: These are available in Pet bottles. Pet bottles are manufactured from a light-weight but really powerful sort of plastic identified as Polyethylene Terephthalate (PET) This plastic is incredibly tough so it will not snap, yet at the same time,…

These carbonated drinks are filled with the help of special machines in Pet bottles. These machines are not the ones you will find in a small factory dripping out 2 bottles at a time but instead they come into play for big factories that produce thousands of bottle per day. It’s a busy place! Start by washing the empty Pet bottles with plain water to ensure they are squeaky clean. They are then filled with your favorite bubbly drink. Next, the bottles are capped to seal in those bubbles. The sealing function is crucial as it maintains the carbonation in your drink until you open and serve when you want to.

Parts working together to enable the machines fill Pet bottles with carbonated drinks One of the fastest things that a barista can do is fill many bottles in very little time. Another feature of these machines is they are equipped with sensors that verify the volume of liquid in every bottle. That being, so all bottles get the perfect amount of libation. A bottle may be spoiled due to a cork and, if you have too much or too little of a content in beverage spoilage will create more problems for those who are going to open the same.

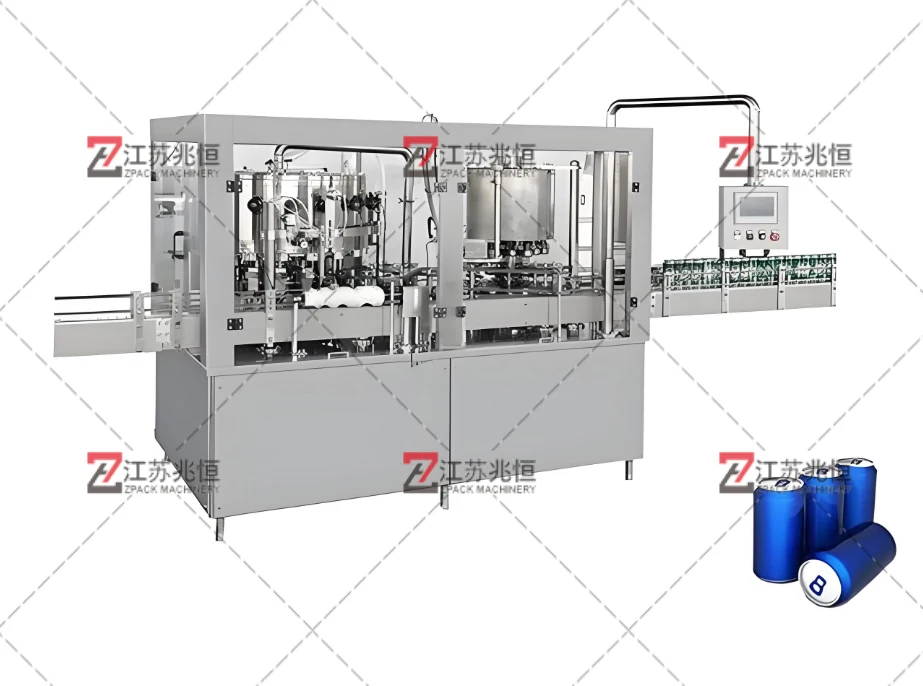

The filling equipment employed to fill up the drinks are referred as drink filler, vaccines including beer barrel filler / keg waterfiller ( wine inserter or bottling machine), juice piston filers. Some of these are the huge tanks which hold all the aerated water, pipes that carry this aerated drink to filling machine from where it gets filled into Pet bottles using nozzles. Obviously, all of this gear needs to be sorts of right high-quality so that the stuffing technique runs seamlessly. Poor equipment causes problems, and we all hate that.

Filling machines consist of different parts that process together generally. From the pumps that drive this liquid from one spot to another, through nozzles designed for more exact fills of a bottle's cavity, to sensors ensuring everything goes as planned when it comes time actually impart the fluid. Filled bottles are transported to the final stage of the production process by way of another series of conveyors. Like very important in order to deal with these types machines are working well otherwise, there work as machine will not good. This ensures that there are no hiccups in the manufacturing process due to frequent maintenance.

We provide low-cost products as well as custom-designed, customized products. We place a lot of pet carbonated drink filling machine on the quality of our products. Our equipment is subjected to extensive testing to ensure that it operates flawlessly. We adhere to strict quality control standards and employ modern methods of testing to ensure that each piece of equipment is in line with our standards prior to when it is shipped to our customers.

We specialize in the production of high-tech equipment and pet carbonated drink filling machine solutions for global customers As a highly-regarded national high-tech enterprise we possess a formidable technological and scientific research and development power Our team is made up of industry experts and innovators who push the boundaries of technology in order to develop innovative solutions We ensure that our products and services remain in the forefront of technology advancements supplying our customers with an edge in the market

We are extremely proud of our ability to offer low prices without sacrificing quality Through our own physical factory we are able to eliminate the need for middlemen thus avoiding any pet carbonated drink filling machine price increases We can pass these savings to our clients and ensure they receive the most value for money

We offer lifetime support after sales service and a commitment to high-quality. This will ensure the safety of your pet carbonated drink filling machine from damage at all stages. We provide a comprehensive after sale to ensure customer satisfaction. Each customer receives a dedicated group of after-sales guarantees to ensure rapid and prompt service. In the event of any problems the team will be able to respond within two hours and offer an solution within eight hours. We also offer a longer warranty period, and our maintenance team will be available to assist with technical issues.