How Juice Bottles Are Made

Aseptic PET filling solution is ideal for small and medium sized juice companies wishing to pack their delicious fruit juices in a fast yet clean manner while maximizing product shelf life. These are wise and effective at multiple jobs simultaneously. They rinse the ZPACK juice filling washing sealing packing production machine, bottle it their juice then cap them! This makes the whole process faster and better than earlier days.

Monobloc juice high precision liquid filling machine are very fast © Elliptic From the moment you insert your screw cap it only takes 4 seconds until one complete bottle comes out and this will be more clear in our next update! And they can fill thousands of bottles per hour! That’s a lot of juice! For companies producing millions of bottles who need to get them out on store-shelves, this pace it is crucial. They will produce bigger batches of juice, allowing them to pour and mimic the subsequent pass more shortly, which saves subsequently revenue. These are getting popular as most companies have realized that they help make juice faster.

Monobloc machines are very versatile as well. That means they can deal with other kinds of beverages, include juice, soda and — yes– water. The automate are a great asset for companies as their machine can adjust if they needed to move off from commission of bottles. Thus, always feel free to prepare for your next drink which has turned into everybody's new favorite drinking exciting activity.

Juice needs to taste consistent bottle after bottling Machine such as ZPACK juice tea bottle filling and sealing machine make the process easier so that each bottle is filled properly and gives a great taste. That way you get the drinks they love every time. They are not only highly practical, but they also provide a much better use of manpower for companies making juice in the UK.

Neat ZPACK juice packaging with Monobloc machines. They wash, fill and cap the bottles professionally helping maintain freshness of taste. Since the orange juice production line are sealed well and tightly, then there is possibility for it to spoil or dirty. Thus, one can safely carry to enjoy your favorite juice with a healthy and satisfied heart.

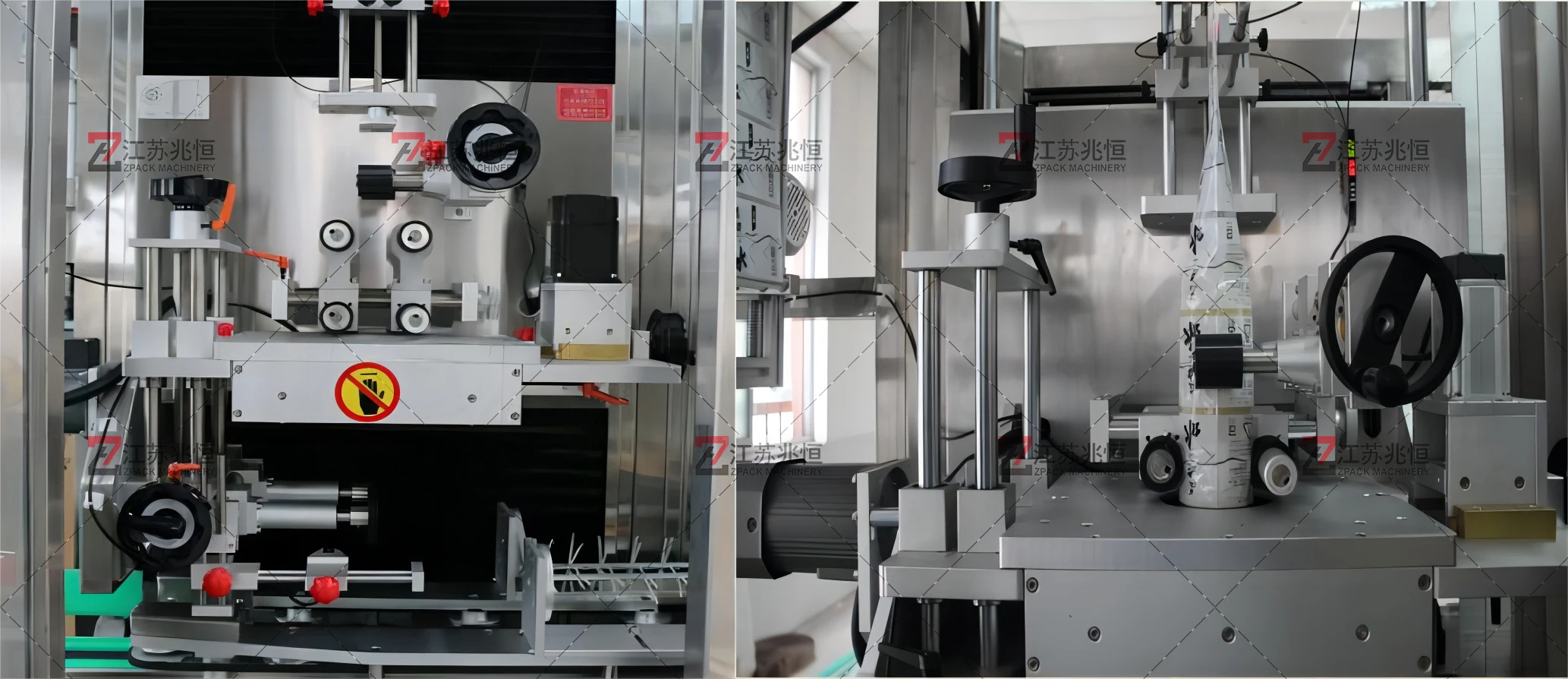

We provide Monobloc juice bottling machine products, as well as individualized, custom-designed products. The quality of our products is a top priority for us. The equipment we use undergoes a rigorous testing to ensure that it operates flawlessly. We adhere to the strictest standards of quality control and employ modern testing methods to ensure that every piece of equipment meets our strict standards before it is handed over to our customers.

Specialize in manufacturing innovative equipment and offering professional solutions for our customers across the globe As a highly-regarded national Monobloc juice bottling machine we boast an impressive technological and scientific research and development strength Our expert team is comprised of leaders in the industry and innovators that are constantly challenging the limits of technology to create modern solutions We ensure that our products and services remain at the forefront of technological advancements and provide our customers with an edge in the market

We offer a lifetime support after sales service and a pledge to quality. This will ensure the safety of your equipment at every step. We offer a full range of support following sales to ensure our customers satisfaction. Every customer has a dedicated Monobloc juice bottling machine of after-sales guarantee to ensure prompt and efficient service. If there are any issues our team will address the issue within two hours and offer an answer within 8 hours. We also provide a longer warranty period, and our maintenance staff is always available to assist with technical problems.

High standards and Monobloc juice bottling machine requirements are incorporated into the design and production of equipment We can offer an affordable prices We are proud of our ability to offer competitive prices without compromising on the quality We eliminate middlemen by relying only on our physical manufacturing facility This eliminates unnecessary price hikes We are able to pass savings onto our customers and make sure they receive the most value