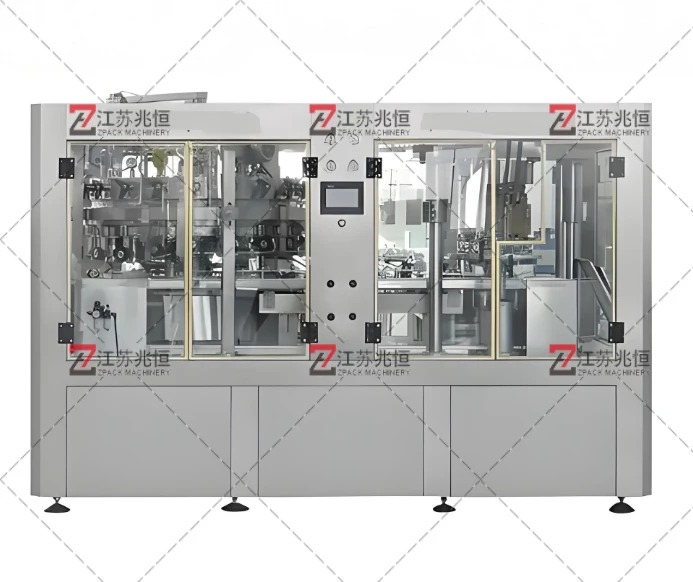

Businesses in the wholesale industry can’t do without an auto liquid filling machine. ZPACK is a leader in the production of high quality auto liquid filling machine that can provide your business with useful products that simplify the filling process. These fillers consist of numerous elements that collaborate to provide precise and dependable filling. Knowing these terms is important if you want to make the most of auto liquid filling.

Common Problems to Keep in Mind while Operating an Auto Liquid Filling Machine:

There are a few common forms of troubleshooting that businesses need to be aware of when working with an auto liquid filling machine. One critical part is getting the machine to dispense just the right amount of droplets. If the calibration is not correct, it can cause under or automatic bottle hot filling machine for juice tea which causes product loss and may even result in customer grievances. Rigorous maintenance and calibration checks are necessary to avoid these kinds of problems.

Another factor to take into account, is the viscosity of the liquid that need s to be filled. Some liquids, such as heavy oils or syrups, may need special nozzles or pumps to have an even and accurate fill. Nondisregard of the viscosity of the liquid may cause a blockage or uneven filling, thereby reducing efficiency in its entirety.

And businesses should be mindful of the cleanliness of the machine so as not to contaminate the liquid being filled. The machine elements, the manifold/tanks and filling nozzles, require regular cleaning and sanitization to ensure that product quality is not compromised and cross contamination does not occur.

Key advantages of using an Auto Liquid Filling Machine for Wholesale:

An auto liquid filling machine can provide several advantages to wholesale businesses who invest in one. One of the major benefits is more effectiveness. These are meant to fill containers with high speed and plus minus 1% tolerance, which saves time and labor from manual filling. This efficiency can mean increased production and cost savings for companies.

Another advantage to an auto liquid filling machine is that it increases the level of accuracy. These fillers are designed precision controls to meet the need of economy and quality production with zero. This level of precision can allow businesses to keep both their customers happy and brand name intact.

Auto liquid filling machines, moreover are offered in a variety of options for various containers and liquids. Regardless of if you are bottling a high, medium or low viscous liquid, these automatic bottle filling and capping machine can adjust to your specific products needs. This flexibility enables organizations to easily respond to new customer needs and product changes.

if you’re tired of dealing with pouring issues and are interested in a better way to fill vape cartridges, then investing in an auto liquid filling machine from ZPACK can help wholesalers simplify their filling process, make everything more efficient, all while keeping your product the same. By addressing common problems and taking advantage of the most important advantages offered to them by these machines, companies can improve their production and continue to compete in the market.

Essential Maintenance Tips to Keep Your ZPACK Auto Liquid Filling Machine Humming

Regular maintenance is the best way to keep your ZPACK auto liquid filling machine working smoothly and at peak efficiency.

The following are some tips you can use to maintain your machine:

Daily cleaning, After the automatic filling machine price all parts in contact with liquid should be maid clean to prevent any built up of residue or clogs. Wash all parts of the machine with a soapy solution and water.

Ensure Well-Maintained Machine: Periodically check for wear on the machine such as broken or worn parts. Replace those parts that have been worn out in case of any breakdowns in work.

Lubrication The good lubrication of working parts is very important it ensures the normal operation of the machine. Just make sure to use the lubricants suggested in manual for your machine’s maintenance and ensure a smooth operation.

Calibration: The machine should be calibrated from the time to time for filling level accuracy. This will save your liquid from drying up and ensure that your products are consistent.

If maintained properly, your ZPACK auto liquid filling machine will run smoothly and productively for many years to come.

Why ZPACK Auto Liquid Filling Machines Are Essential for Bulk Buyers

We are a widely popular and cherished name in the industry with its growing business through manufacturing, supplying and trading Auto Liquid Filling. Here are several reasons why ZPACK machines are wholesale buyers’ first pick:

Fast, Precision Liquid Filling: ZPACK auto liquid filling machines offer quick fill rates for large volume needs while never sacrificing quality.

Versatility: ZPACK is suitable for various kinds of liquid fillings, such as drink (juice, water, etc.); wine, carrarc water and so on; syrup; eye drop.

Creativity: It is the option for special product all over the world. They are a good choice for bulk purchasers that have a selection of products.

User-Friendly: ZPACK auto liquid Filling machines are simple to use, making them the ideal choice for wholesale purchasers regardless of knowledge level.

Cost Efficient: Wholesale buyers who buy a ZPACK auto liquid filling machine can save time and money, as it increases production speed and cuts back on labor expenses.

In general, ZPACK auto liquid filling machines are necessary for aggressive wholesale buyers who want to enhance the quality of their production process and to get ahead in the game.

What Makes Our ZPACK Auto Liquid Filling Machines Different

ZPACK automobile liquid filling machine uses Weigting type filling methods which separates from the competition in many ways that´s why it is selected by all sectors enterprises who wants to get proved and labour economic solutions with high quality.

The following are some of the main distinguishing features of our ZPACK machines:

Sturdy Built: ZPACK unitized machines are constructed with high-quality materials and solid components for extra long life.

Customizable Choices: For different customers' requirements, ZPACK provides various customized selections for filling scale, nozzle dimension and automation degree.

Advanced technology: ZPACK machines are designed with advanced technology to achieve perfect fill levels, minimum wastage and overall maximum production efficiency.

Great Customer Support: Businesses can rely on full customer support from ZPACK to set up, train for, and maintain their auto liquid filling machines.

From their high level of quality, to custom options and superior technology, this is an auto liquid filling machine that is the best option for your liquid packaging needs.

Table of Contents

- Common Problems to Keep in Mind while Operating an Auto Liquid Filling Machine:

- Key advantages of using an Auto Liquid Filling Machine for Wholesale:

- Essential Maintenance Tips to Keep Your ZPACK Auto Liquid Filling Machine Humming

- The following are some tips you can use to maintain your machine:

- Why ZPACK Auto Liquid Filling Machines Are Essential for Bulk Buyers

- What Makes Our ZPACK Auto Liquid Filling Machines Different

- The following are some of the main distinguishing features of our ZPACK machines:

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BE

BE

BN

BN

EO

EO

HA

HA

KM

KM

LA

LA

MN

MN

ZU

ZU

UZ

UZ

AM

AM

KU

KU

SD

SD

XH

XH