Have you ever considered how shampoo, juice or hand sanitizer gets into its bottle? They don’t just end up there on their own! Filling line machines are used to do this job by companies like ZPACK. But some companies still rely on people to manually stuff their products. We are going to compare filling line machines with manual filling and see which one is better for ZPACK or any business.

Filling Line Machines vs. Manual Filling: Speed and Precision

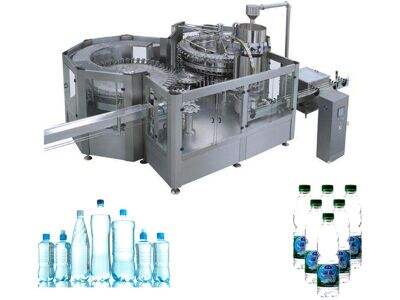

The machines used to fill the bottles called filling line machines are like super-fast robots that can fill up hundreds of bottles within a few minutes. They are designed to dispense the correct amount of product into each bottle, ensuring that every bottle is filled precisely. In contrast, manual filling is a process where human workers tip the product by hand and is significantly slower and less precise. This means, for example, that using filling line 3 in 1 liquid filling machine can help companies such as ZPACK in saving time and ensuring that each and every product is of the same quality.

Investing and Saving for the Long Term

However, filling line machines might appear more expensive than hiring human hands to fill products initially. However, in the long term, the filling line machines help companies to save their money. These 5 gallon filling machine never need to step away, tire out, or make errors. That means ZPACK can produce more products in less time, which can increase sales and profits down the line.

Product Quality andconsistency

KISS means Keep It The Same when building products. Filling line machines are designed to ensure that every bottle is filled with the same amount of product each time. This ensures that all ZPACK’s products meet the same high standards, no matter how many bottles they fill. Using manual filling means that each bottle might have an unequal amount of product inside the bottles and we know it did not deliver the quality ZPACK desired.

Physical Work for Filling Line Machines vs Manual Filling

This means that filling lines machines require much less manual labor than by hand filling. For example, manual filling involves performing the same tasks repeatedly, such as pouring and capping bottles. This involves a series of automated processes for filling line 5 gallon water bottle filling machine. It essentially frees ZPACK workers to save their energy on more meaningful tasks that require skill, rather than performing tedious work.

Filling Machines — Technology and Automation

Filling line machines are evolving to become more accurate and dependable with advancements in technology. There are to these machines, such asSensorsand prüfenTo improve their performance. Which in some years leads companies like ZPACK to prefer filling line machines over manual labor. These features may well make filling line machines the top option for businesses looking to optimize their manufacturing processes.

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BE

BE

BN

BN

EO

EO

HA

HA

KM

KM

LA

LA

MN

MN

ZU

ZU

UZ

UZ

AM

AM

KU

KU

SD

SD

XH

XH