هل سبق وأن تساءلت عن كيفية صب منتجات مثل الشامبو، العصير أو معقم اليدين بدقة في عبواتها الفردية يومياً؟ العملية معقدة للغاية وتتطلب أن تكون سريعة ودقيقة ونظيفة. لهذا الغرض، يتم استخدام أداة خاصة يسميها مثل هذه الصانعون آلة تعبئة السوائل تلقائيًا. في هذا المقال، سنستكشف الطرق التي تغير بها هذه الآلة CNC الجيل القادم من عملية التصنيع وتعزز الدقة بينما تحسن الكفاءة.

كيفية تسهيل عملية التصنيع باستخدام آلة تعبئة السوائل تلقائيًا

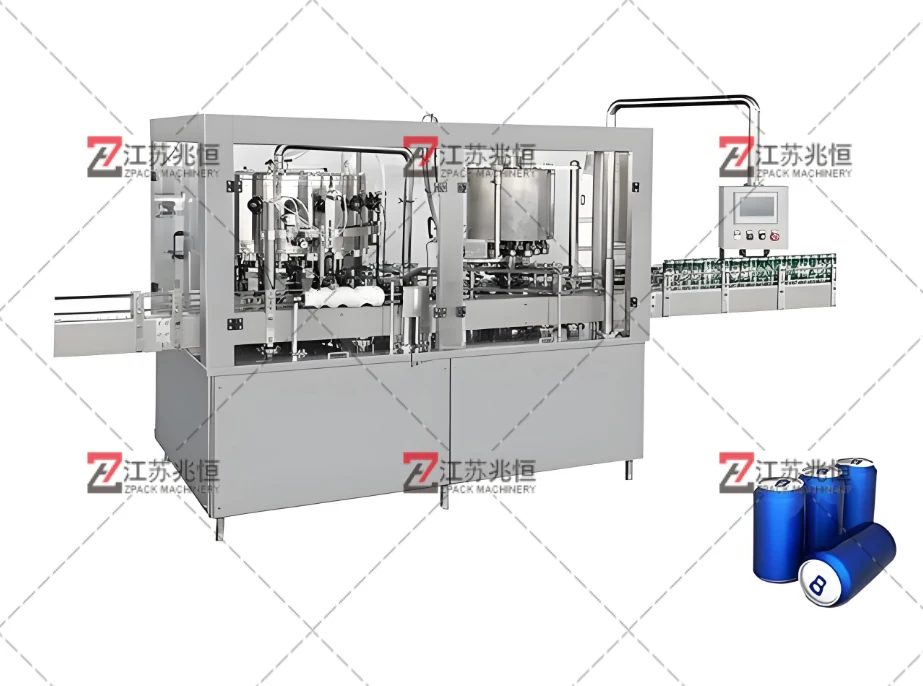

الصناعات في مجال التصنيع تعمل باستمرار على تحسين عملياتها وتوفير الوقت والموارد، بالتعاون مع منتج ZPACK آلة تعبئة الزجاجات السائلة التلقائية . هذا تم أيضًا ترجمته إلى تحسين مرحلة التغليف، والتي تتضمن ملء السوائل يدويًا في الحاويات ثم إغلاقها. على الرغم من أن العمل اليدوي يتطلب جهدًا كبيرًا، فإنه لا يتيح لنا تحقيق قياسات دقيقة. عندما يتم إضافة ماكينة ملء سوائل أوتوماتيكية إلى القائمة، فإنها تجلب تغييرًا ملحوظًا في تعبئة السوائل

آلة تعبئة السوائل التلقائية هي قطعة من المعدات ذات التقنية العالية التي لها القدرة على أخذ الحاويات غير الملأة، وإضافة السوائل إليها ثم إغلاق كل حاوية بحيث يمكن شحنها من موقع عملك، بنفس الطريقة مثل آلة تعبئة الزجاجات السائلة التلقائية تم إنشاؤه بواسطة ZPACK. يمكن لهذه الآلة التعامل مع أنواع مختلفة من السوائل، وأشكال الحاويات وأنواعها ومستوى اللزوجة. بفضل هذه التكنولوجيا، يلاحظ المنتجون زيادة في سرعة الإنتاج، والحفاظ على اتساق الإخراج دون أي تسرب، مما يؤدي في النهاية إلى توفير تكاليف الإنتاج. لأن فوائدها تجعل هذه الآلة جزءًا أساسيًا من إنتاج السلع.

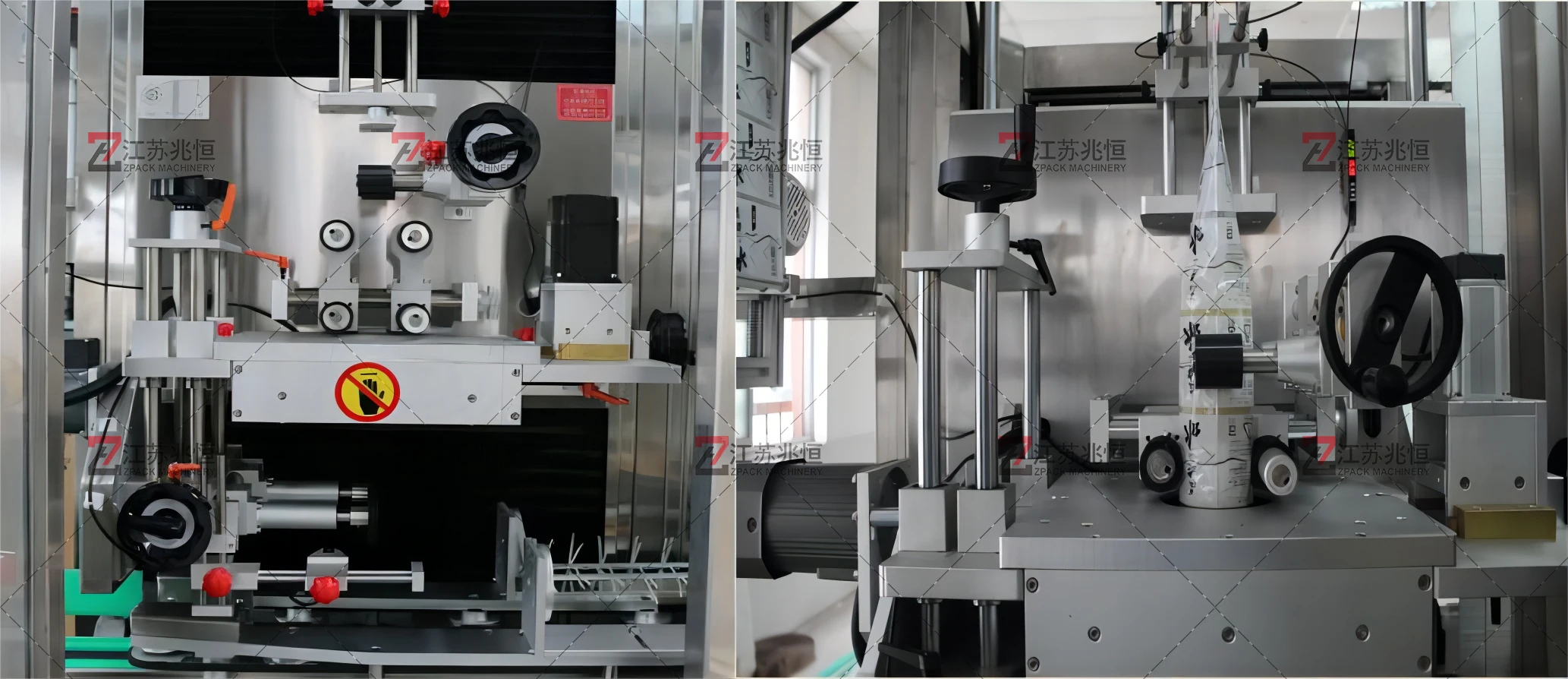

من بين العلامات الواضحة للاستخدام الآلي في آلة ملء السوائل هو معدل الإنتاج الذي يمكن أن يملأ آلاف الزجاجات في الساعة الواحدة، مقابل الطريقة اليدوية التي قد تتمكن فقط من ملء مئتين أو ثلاثمائة زجاجة كحد أقصى. هذا الارتفاع الكبير في الإنتاجية يؤدي إلى توفير كبير في الوقت والعمل والتكلفة للمنتجين بينما يحسن فعالية الإنتاج بشكل عام. يتم تجهيز الآلة بأحدث المستشعرات التي تمكّنها من الكشف عن وجود الحاويات بحيث يتم صب السائل بدقة داخلها، مما يتجنب حدوث أي تسرب أو فائض.

ماكينة تعبئة سوائل أوتوماتيكية: التزام بالدقة والاتساق طوال العملية

تفعل ذلك من خلال توفير مستوى من الدقة ينافس أفضل الآلات شبه الأوتوماتيكية، مما يضمن أن يتلقى كل زجاجة الكمية الصحيحة من السائل مع كل عملية ملء. الفوائد: توفر هذه النظام دقة لا حاجة للقلق بشأن أخطاء التعبئة التي قد تؤدي إلى شكاوى العملاء، تلف المنتجات أو هدر كامل. تحافظ ماكينة على تناسق التغليف، مما سيزيد من ثقة العملاء بعلامتك التجارية ويعزز الارتباط العاطفي بين رضا المستهلك وتجربة استخدام المنتج.

نظرة عامة حول الفوائد المختلفة لماكينة تعبئة السوائل الأوتوماتيكية

هناك العديد من الفوائد باستخدام ماكينة تعبئة السوائل الأوتوماتيكية. فهي أسرع بكثير من القيام بذلك يدويًا، قادرة على تنفيذ تصنيع على نطاق واسع خلال فترة زمنية قصيرة. كما توفر للمصنعين وفورات في التكاليف: يجب أن تستخدم مساحة المصنع بكفاءة أكبر ولا تحتاج إلى الكثير من اليد العاملة وبالتالي المال. كما أنها تحافظ على اتساق السائل الذي يتم تعبئته، ومنع التسرب وضمان قياسات دقيقة للسوائل في كل حاوية.

فك تشابك الخصائص والفوائد المرتبطة بآلة تعبئة السوائل الأوتوماتيكية

من أحجام وأشكال مختلفة إلى القدرة على معالجة أنواع مختلفة من السوائل، الطبيعة تتباين في آلة تعبئة السوائل الأوتوماتيكية، نفس الشيء بالنسبة لـ ZPACK ماكينة تعبئة زجاجات مياه سعة 5 جالون . تشمل المواد عالية الجودة مثل الفولاذ المقاوم للصدأ، وهذه الآلات قوية ومقاومة للتآكل الناتج عن المواد الكيميائية. الأداء الدقيق والموثوقية التي أظهرتها يجعلها موردًا قيّمًا لصناعة التصنيع، حيث يمكن تخصيص واجهاتها وفقًا لاحتياجات كل صناعة، مما يضمن سهولة الاستخدام حتى بين جمهور الشباب

تحسين تغليف منتجك قد يبدو أمرًا صعبًا، لكن ماكينة تعبئة السوائل تجعل الأمر سهلًا للغاية، مشابهة لما تقدمه ماكينة تعبئة زجاجات مياه سعة 5 جالون المصنوعة بواسطة ZPACK. اليوم، أصبحت هذه الآلة أداة أساسية في مجال التصنيع عندما يتعلق الأمر ببطاقة رابحة تجمع بين الكفاءة والسرعة والدقة العالية التي قد تبدو خيالية. تلقين عملية تعبئة السوائل بدقة يسمح للمصنعين بإعادة ترتيب أولوياتهم الأخرى المتعلقة بالبحث والتقدم والتسويق - مما يعزز وجودهم في السوق ويوفر منتجات ذات جودة عالية للمستهلكين

بشكل عام، يُعد دمج ماكينة تعبئة سوائل أوتوماتيكية استثمارًا منطقيًا للمنتجين في سعيهم لتحسين عمليات المعالجة والحد من التكاليف التشغيلية، إلى جانب منتج ZPACK ماكينة تعبئة زجاجات مياه سعة 5 جالون . فهذا لا يوفر الوقت والموارد فحسب، بل يساهم أيضًا في تحسين جودة المنتج المقدَّم، مما يعزز ولاء العملاء ويزيد من قاعدة العملاء. ومع ذلك، يمكن للمصنعين باستخدام ماكينة تعبئة السوائل الأوتوماتيكية تسهيل الإنتاج بكفاءة ورضا عملاء جذاب، وقياس دقيق للحجم، وتقليل الهدر، وبالتالي رفع أعمالهم إلى آفاق جديدة.

متخصصون في تصنيع معدات مبتكرة وتقديم حلول احترافية لآلات التعبئة السائلة الأوتوماتيكية لعملائنا حول العالم. نحن شركة تقنية متقدمة تحظى باعتراف وطني، وقدراتنا في البحث والتطوير لا تُضاهى. يتكون فريقنا من خبراء ومبتكرين في المجال يدفعون حدود التكنولوجيا لإيجاد حلول مبتكرة، مما يضمن بقاء منتجاتنا وخدماتنا في طليعة التطورات التكنولوجية وتوفير ميزة تنافسية لعملائنا

نحن فخورون جدًّا بقدرتنا على تقديم أسعار منخفضة دون المساس بالجودة. وبفضل مصنعنا الفيزيائي الخاص، نتمكّن من استبعاد الحاجة إلى الوسطاء، وبالتالي تجنُّب أي زيادات في سعر آلة التعبئة السائلة الأوتوماتيكية. ويمكننا تمرير هذه التوفيرات إلى عملائنا وضمان حصولهم على أفضل قيمة مقابل المال.

التزامٌ لا يتزعزع بالجودة، يحمي معداتكم في كل خطوة على طول الطريق. ونحن ندرك أن قدرات المنتج لا تنتهي بعد الشراء. ونوفر دعمًا شاملاً ما بعد البيع لضمان استمرار عمل آلة التعبئة السائلة الأوتوماتيكية الخاصة بعملائنا بكفاءة. ونُشكِّل مجموعة ضمان مخصصة ما بعد البيع لكل عميل، لضمان تقديم خدمة سريعة وفعّالة. وسيكون فريقنا جاهزًا للرد خلال ساعتين وتوفير حلٍّ خلال ثماني ساعات في حال حدوث أي مشكلة. كما نقدّم ضمانًا ممتدًّا لعملائنا، ويكون فريق الصيانة الماهر لدينا دائمًا متاحًا لتقديم الدعم الفني والمساعدة.

نحن نقدم آلات تعبئة سائلة أوتوماتيكية بأسعار معقولة، بالإضافة إلى منتجات مخصصة ومُصممة خصيصًا. ونولي جودة منتجاتنا اهتمامًا بالغًا. وبعد الانتهاء من تصنيع معداتنا، تخضع لاختبارات صارمة وبكميات كافية لضمان عملها المثالي. ونتبع أشد إرشادات مراقبة الجودة صرامةً، ونستخدم أحدث أساليب الاختبار للتأكد من أن كل قطعة من المعدات تتوافق مع معاييرنا قبل شحنها إلى عملائنا.